Bestaand pomp - Circulatie

Vervangingspomp - Hoog Efficiënt Premium Smart Uitwisseltabel

Commentaar

Productinformatie

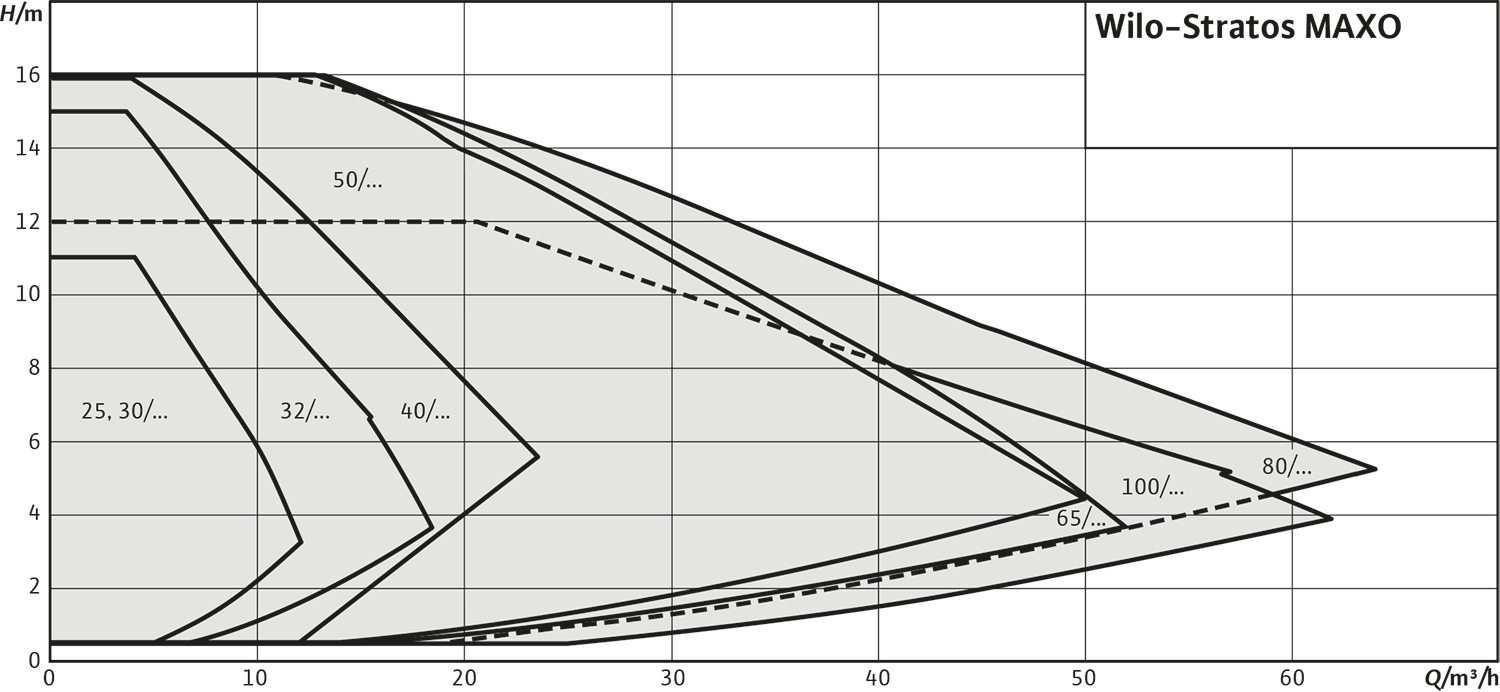

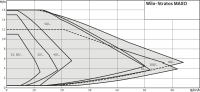

Stratos MAXO 25/0,5-6

Bijzonderheden/productvoordelen

- Energiebesparing door hogere systeemefficiëntie met de Q-Limit functie (debietbegrenzing)

- Verbeterde energie-efficiëntie-index EEI ≤ 0,20 bij alle enkelpompen.

- Geoptimaliseerd display voor betere leesbaarheid en bediening

- Plaatsbesparende montage door compacte constructie en situatie-onafhankelijk LC-display.

- Modulair concept voor verbinding met alle gangbare bussystemen (bijv. Modbus, BACnet, CAN, LON, PLR)

- Beproefde kwaliteit en betrouwbaarheid

Natlopercirculatiepomp met draad- of flensaansluiting, EC-motor met automatische vermogensaanpassing

Toepassing

Warmwaterverwarmingen van alle systemen, klimaatinstallaties, gesloten koelcircuits, industriële circulatie-installaties

Uitrusting/werking

Bedrijfssituaties

- Regelbedrijf (n=constant)

- Δp-c voor constante verschildruk

- Δp-v voor variabele verschildruk

- Δp-T voor temperatuurgestuurde verschildruk (via IR-stick, IR-monitor, Modbus, BACnet, LON of CAN programmeerbaar)

- Q-Limit voor de begrenzing van het maximale debiet (instelling alleen via IR-stick)

- Instelling van de bedrijfssituatie

- Instelling verschildruksetpoint

- Instelling automatische verlaging

- Instelling pomp AAN/UIT

- Instelling van het toerental (stuurbedrijf)

- Traploze vermogensaanpassing afhankelijk van de bedrijfssituatie

- Automatische verlaging

- Deblokkeerfunctie

- Softstart

- Volledige motorbeveiliging met geïntegreerde uitschakelelektronica

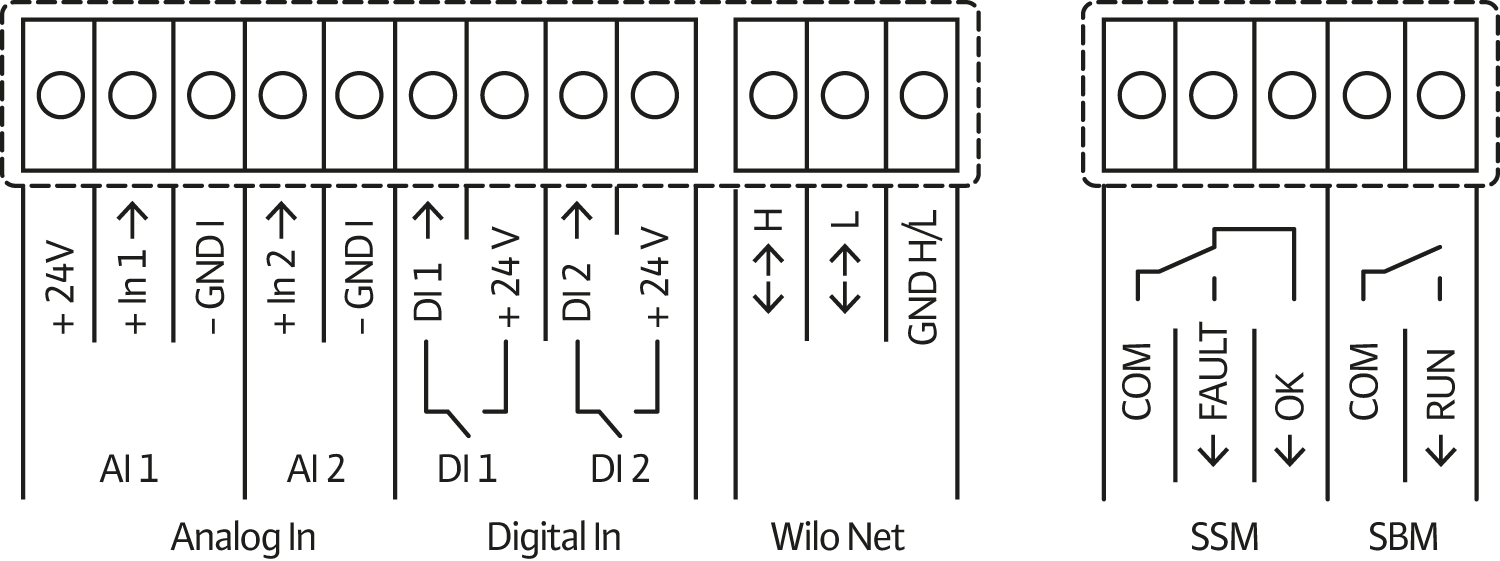

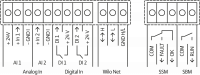

- Besturingsingang "voorrang uit" (met IF-modules Stratos mogelijk)

- Besturingsingang "voorrang min" (met IF-modules Stratos mogelijk)

- Besturingsingang "analoog in 0 - 10 V" (toerentalafstandsbediening) (met IF-modules Stratos mogelijk)

- Besturingsingang "analoog in 0 - 10 V" (setpointafstandsbediening) (met IF-modules Stratos mogelijk)

Meldings- en weergavefuncties

- Verzamelstoringsmelding (potentiaalvrij verbreekcontact)

- Enkelbedrijfsmelding (potentiaalvrij maakcontact) (met IF-modules Stratos mogelijk)

- Storingsindicatielamp

- LC-display voor de weergave van pompgegevens en foutcodes

- Infrarood-interface voor draadloze gegevensuitwisseling met IR-stick/IR-monitor

- Seriële digitale interface Modbus RTU voor aansluiting op een gebouwbeheersysteem GBS via BUS-systeem RS485 (mogelijk met IF-modules Stratos).

- Seriële digitale interface BACnet MS/TP Slave voor aansluiting op een gebouwbeheersysteem GBS via BUS-systeem RS485 (mogelijk met IF-modules Stratos)

- Seriële digitale interface CAN voor aansluiting op een gebouwbeheersysteem GBS via BUS-systeem CAN (mogelijk met IF-modules Stratos)

- Seriële digitale interface LON voor de aansluiting op een LONWorks-netwerk (mogelijk met IF-modules Stratos)

- Seriële digitale interface PLR voor de aansluiting op gebouwbeheersysteem via Wilo-interfaceconverter of firmaspecifieke koppelmodules (mogelijk met IF-modules Stratos)

- Hoofd-/reservebedrijf (automatische storingsomschakeling/tijdafhankelijke pompwissel): verschillende combinaties met IF-modules Stratos (toebehoren) mogelijk

- Parallel bedrijf (rendementsgeoptimaliseerde pieklastbij- en uitschakeling): verschillende combinaties met IF-modules Stratos (toebehoren) mogelijk

- Steeksleutelaanzet aan het pomphuis (bij pompen met schroefdraadkoppeling met P2< 100 W)

- Bij flenspompen: Flensuitvoeringen

- Standaarduitvoering voor pompen DN 32 tot DN 65: combiflens PN 6/10 (flens PN 16 conform EN 1092-2) voor tegenflenzen PN 6 en PN 16

- Standaarduitvoering voor pompen DN 80 / DN 100: flens PN 6 (gedimensioneerd PN 16 conform EN 1092-2) voor tegenflens PN 6

- Speciale uitvoering voor pompen DN 32 tot DN 100: flens PN 16 (conform EN 1092-2) voor tegenflens PN 16

- Aansluiting voor optionele uitbreiding met Wilo-IF-modules

- Standaard warmte-isolatie voor verwarmingstoepassingen

- Pomp

- Incl. warmte-isolatie

- Incl. afdichtingen bij draadaansluiting

- Incl. carrosserieringen voor flenzen (bij nominale aansluitdiameters DN 32 - DN 65)

- Incl. inbouw- en bedieningsvoorschriften

- Toegestaan temperatuurbereik -10 °C tot + 110 °C

- Netaansluiting 1~230 V, 50/60 Hz

- Beschermingsklasse IP X4D

- Draadaansluiting resp. flensaansluiting (afhankelijk van het type) Rp 1 tot DN 100

- Max. bedrijfsdruk standaarduitvoering: 6/10 bar resp. 6 bar (speciale uitvoering: 10 bar of 16 bar)

- Pomphuis: gietijzer met KTL-coating

- Warmte-isolatie: Polypropyleen

- As: Roestvrij staal

- Lager: Kool, met metaal geïmpregneerd

- Waaier: Kunststof

- Natloper-circulatiepomp met EC-motor en geïntegreerde automatische vermogensaanpassing

- Rode-knop-technologie en grafisch display

- Motorbeveiliging met uitschakelelektronica

- Steekverbinding voor de functie-uitbreiding met optionele IF-module voor de gebouwautomatisering (GA)

- Waaier met driedimensionaal gekromde schoepen en kunststof spleetbus van CFK

Geprefabriceerde diffusiebestendige isolatieschaal, ontworpen voor Wilo-Stratos MAXO-pompen. Bij voorkeur gebruikt in airconditioning- en koelsystemen. Dit om condensatie te voorkomen en energieverliezen te minimaliseren.

- Levering inclusief Armaflex tape voor afdichting tussen isolatie en pompflens.

- Medium temperatuurbereik -10 °C tot 110 °C.

- Gemaakt van Armaflex-materiaal.

- Waterdamp door diffusieweerstand µ ³ 10.000

- Warmtegeleiding 0,033 W (m . K)

- Eenvoudige installatie, tijdsbesparing

- Rendabele totaaloplossing

- Installatie van lekbak is niet nodig.

- Past op alle Stratos-MAXO-pompen

- Past op alle Stratos-MAXO-pompen

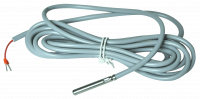

Aansluiting op de Stratos MAXO voor het detecteren van de temperatuur van het medium bij temperatuursafhankelijke pompsturing of voor het detecteren van verwarmings-/koelhoeveelheden.

- Sensor Pt 1000 klasse AA, ø6 x 40 mm

- Kabellengte: 3 m

- Meetbereik: -5 °C tot 70 °C, kortstondig tot 90 °C

Aansluiting op Stratos Maxo-Z voor meting van de warmwater retourtemperatuur bij de boiler om de thermische desinfectie te detecteren.

- Sensor Pt 1000 klasse B, ø8,5 x 35 mm

- Kabellengte 5 m

- Meetbereik -5 °C tot 70 °C, kortstondig tot 90 °C.

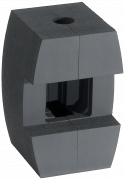

Voor de bevestiging van de dompelsensor Pt 1000 AA voor aansluiting op Stratos MAXO.

- Schroefdraad: G ½

- Binnendiameter: 6,4 mm voor sensor tot ø6 mm

- Schroeflengte 45 mm voor installatie in een schroefdraad-T-stuk en bruikbaar voor leidingen vanaf ca. DN 25 tot DN 50

Algemene functies

Seriële digitale interface voor aansluiting aan het gebouwbeheersysteem GBS voor de overdacht van gegevens zoals:

- Besturingscommando's voor de pomp

- Meldingen van de pomp

- Proceswaarden

Algemene functies

Seriële digitale interface voor aansluiting aan het gebouwbeheersysteem GBS voor de overdacht van gegevens zoals:

- Besturingscommando's voor de pomp

- Meldingen van de pomp

- Proceswaarden

Algemene functies

Seriële digitale interface voor aansluiting aan het gebouwbeheersysteem GBS voor de overdacht van gegevens zoals:

- Besturingscommando's voor de pomp

- Meldingen van de pomp

- Proceswaarden

Algemene functies

Seriële digitale interface voor aansluiting aan het gebouwbeheersysteem GBS voor de overdacht van gegevens zoals:

- Besturingscommando's voor de pomp

- Meldingen van de pomp

- Proceswaarden

Kan worden gebruikt met de Wilo-Assistant-app en de Smart Connect-tool.

Gegevensoverdracht is als volgt mogelijk:

- Van de pomp naar de Smart Gateway via een bedrade Wilo Net-verbinding

- Van Smart-Gateway tot Smart Cloud via een bekabelde Ethernet-verbinding met internet toegang

- Van de cloud naar de Smart Connect-app op uw mobiel apparaat, internetverbinding (via mobiel netwerk of wifi)

- Snelle bi-directionele overdracht van operationele gegevens en instellingen tussen Wilo-pompen en Wilo-Smart Cloud in realtime

- Mogelijkheid om tot 10 pompen aan te sluiten

- Gemonteerd op DIN-rail volgens norm DIN 43880

- Bedrijfstemperatuur: 0 - + 60 °C

- Voedingsspanning: 24 V DC (min. 18 V / max. 27 V)

- Beschermingsklasse: IP 20

- Elektromagnetische compatibiliteit: EN 55032 klasse B

- Storingsoverdracht: EN 61000-6-3

- Interferentiestabiliteit: EN 61000-6-2

- Afmetingen (hoogte x breedte x lengte): 90 x 56 x 162 mm

- Gewicht: 0,4 kg

Algemene functies

Seriële digitale interface voor aansluiting aan het gebouwbeheersysteem GBS voor de overdacht van gegevens zoals:

- Besturingscommando's voor de pomp

- Meldingen van de pomp

- Proceswaarden

Algemene functies

Seriële digitale interface voor aansluiting aan het gebouwbeheersysteem GBS voor de overdacht van gegevens zoals:

- Besturingscommando's voor de pomp

- Meldingen van de pomp

- Proceswaarden

Temperatuursensor bedoeld voor Stratos MAXO -R7 en Stratos MAXO-D -R7.

Functies:

- Bediening via regelmodus T-constant en ΔT-constant

- Nachtverlaging

- Meting van verwarmings- en koelenergie

- Automatisch omschakeling verwarmings-/koelstand

De sensor meet het drukverschil tussen de zuig- en persaansluitingen naar de leidingen en zet dit om in een elektrisch signaal van 4-20 mA, dat door de frequentie-omvormer wordt gebruikt om de druk van de pomp te regelen. De waarde van de uitgangsstroom is evenredig met de verschildruk.

- Geschikt voor wandmontage

- Nominale spanning: 24 V DC

- Bedrijfsspanning: 15 - 30 V DC

- Uitgangssignaal van sensor: 4-20 mA

- Beschermingsklasse: IP 55

- Kabel 3 x 0,34 mm²

- Bestemd voor koperen buizen 6 mm

- Kabellengte 5 m

- Mediumtemperatuur: -20 °C tot + 80 °C

- Omgevingstemperatuur: 0 °C tot + 70 °C

- Afmetingen: 78 x 79,5 x 32 mm

- Bruto gewicht: 0,8 kg

- Complete kit

Vervangingspomp - Hoog Efficiënt Standaard Uitwisseltabel

Commentaar

Productinformatie

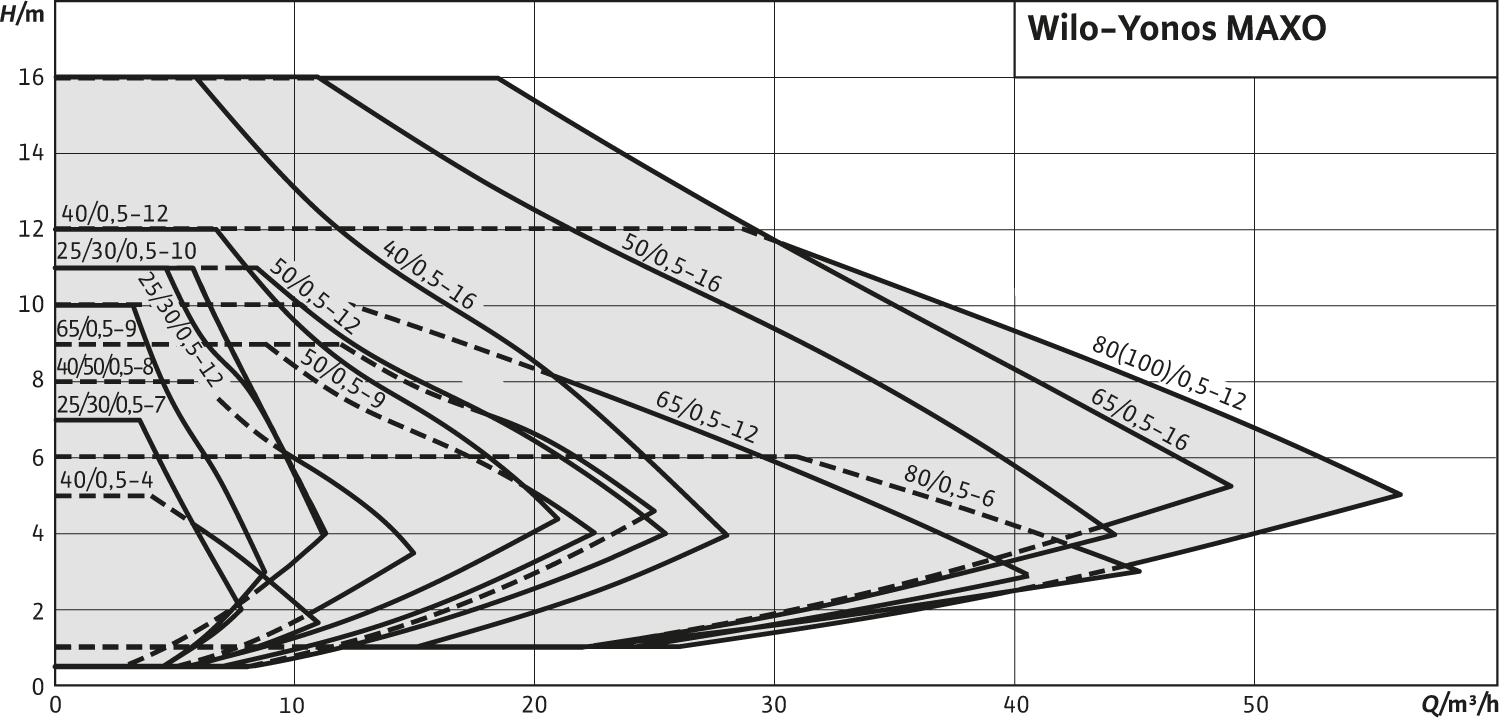

Yonos MAXO 25/0,5-7

- Ledweergave biedt volledige transparantie over gewenste opvoerhoogte, toerentalniveau en mogelijke fouten

- Eenvoudige instelling via drie toerentalniveaus bij het vervangen van een ongeregelde standaardpomp

- Vereenvoudigde elektrische aansluiting door Wilo-stekker

- Garantie van de beschikbaarheid van de installatie door verzamelstoringsmelding

- Compacte constructie en beproefde eenvoudige bediening

Natloper-circulatiepompen met draad- of flensaansluiting, EC-motor met automatische vermogensaanpassing

Toepassing

Warmwaterverwarmingen van alle systemen, klimaatinstallaties, gesloten koelcircuits, industriële circulatie-installaties

Uitrusting/werking

Bedrijfssituaties

- Δp-c voor constante verschildruk

- Δp-v voor variabele verschildruk

- n = constant (3 toerentalniveaus)

- Instelling van de bedrijfssituatie

- Instelling van het pompvermogen (opvoerhoogte)

- Instelling van de toerentalniveaus

- Traploze vermogensaanpassing afhankelijk van de bedrijfssituatie

- Deblokkeerfunctie

- Softstart

- Geïntegreerde volledige motorbeveiliging

- Verzamelstoringsmelding (potentiaalvrij verbreekcontact)

- Storingsindicatielamp

- Led-segmentindicatie voor de weergave van opvoerhoogte en foutcodes

- Weergave van het ingestelde toerentalniveau (C1, C2 of C3)

- Steeksleutelaanzet aan het pomphuis (bij pompen met schroefdraadkoppeling)

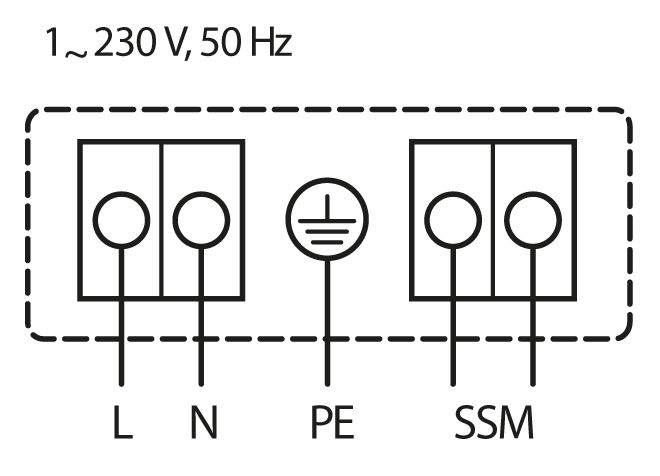

- Elektro-snelaansluitkabel met Wilo-stekker. Voor het aansluiten van de net- en SSM-leiding, met geïntegreerde trekontlasting

- Bij flenspompen: Flensuitvoeringen

- Standaarduitvoering voor pompen DN 40 tot DN 65: combiflens PN 6/10 (flens PN 16 conform EN 1092-2) voor tegenflenzen PN 6 en PN 16

- Standaarduitvoering voor pompen DN 80 / DN 100: flens PN 6 (gedimensioneerd PN 16 conform EN 1092-2) voor tegenflens PN 6

- Pomp

- Incl. afdichtingen bij draadaansluiting

- Incl. onderlegschijven voor flensschroeven (bij nominale aansluitdiameters DN 40 - DN 65)

- Incl. inbouw- en bedieningsvoorschriften

- Toegestaan temperatuurbereik -20 °C tot +110 °C

- Netaansluiting 1~230 V, 50/60 Hz

- Beschermingsklasse IP X4D

- Flensaansluiting DN 32 tot DN 80

- Max. werkdruk, standaarduitvoering: 6/10 bar of 6 bar (speciale uitvoering: 10 bar)

- Pomphuis: Gietijzer met KTL-coating

- As: Roestvrij staal

- Lager: Kool, met metaal geïmpregneerd

- Waaier: Kunststof

- Thermische isolatie van pomphuis bij verwarmingstoepassingen.

- Vermindert warmteverlies tot 85 %

- energiebesparing, verlaagt de operationele kosten.

- Beschermt de pomp tegen externe schade

- 100 % recycleerbaar

De Wilo-Connect module Yonos MAXO wordt op de elektronische module van de pomp geplaatst ter hoogte van de Wilo plug.

Het gebruik van de Wilo-Connect-module Yonos MAXO schrapt externe schakelaars en ander schakelapparatuur, evenals de bijbehorende installatie werkdruk. De belasting van de schakelaars (relais) aan klantzijde als gevolg van hoge startstromen wordt tot een minimum beperkt door de Connect-module Yonos MAXO.

Uitrusting / functie:

- Weergave bedrijfsmelding

- Collectieve storingsmeldilng SSM als potentiaalvrij verbreekcontact

- Collectieve bedrijfsmelding SBM als potentiaalvrij maakcontact

- Besturingsingang extern Off

- Geïntegreerd dubbelpompmanagement met de functies:

- Hoofd- / reservebedrijf met looptijdafhankelijke (24 uur) omschakeling van hoofd- naar reservepomp

- Foutgevoelige omschakeling naar operationele standby-pomp